Role of HVAC in Pharma

In pharmaceutical manufacturing, space conditions directly impact the product being made. To comply with FDA and cGMP, HVAC maintains critical parameters and product integrity by:

- Controlling airborne particles and microorganisms through HEPA filtration.

- Maintaining positive/negative room pressures for clean classification.

- Regulating relative humidity (RH).

- Maintaining stable temperature that directly or indirectly affects production.

Our optimized designs target high energy efficiency (HVAC often >50% of building energy) without diluting guideline compliance.

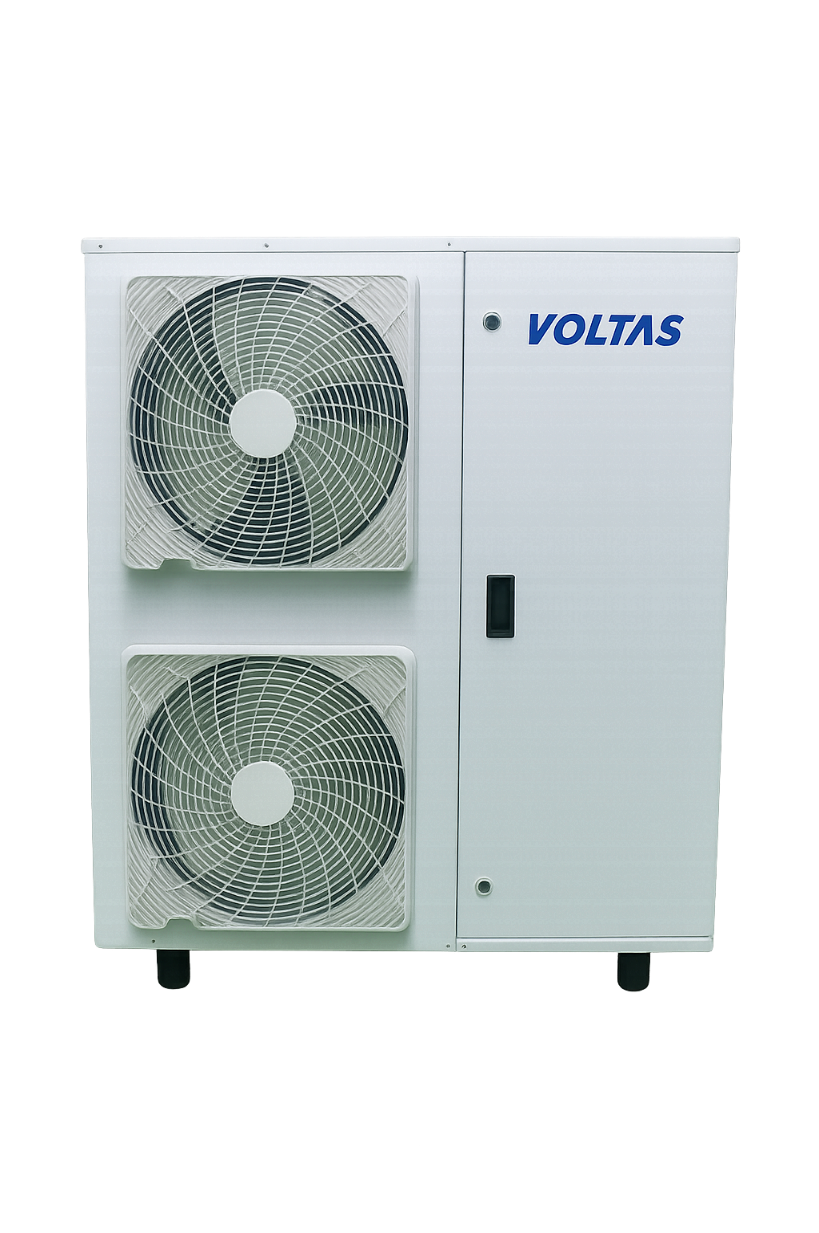

DX System & Air Handling Units

High-efficiency DX systems paired with AHUs deliver precise temperature/RH, with appropriate filtration stages up to HEPA (H14, 99.997% @ 0.3µm).

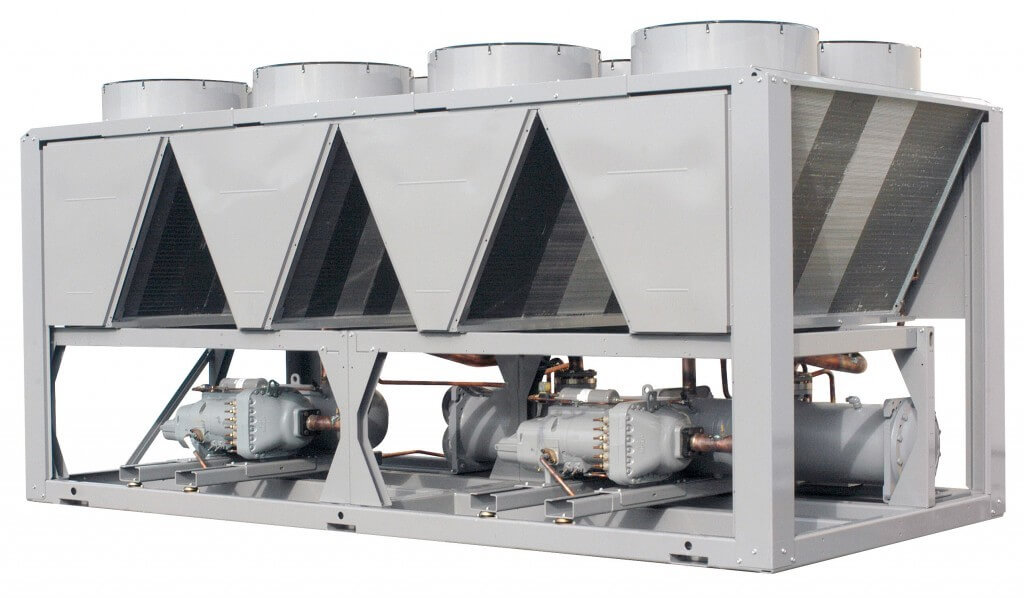

Chillers, Air Distribution & Dehumidification

Chilled-water plants integrated with balanced supply/return/RA/EA ducting, pressure cascades, and dedicated dehumidifiers achieve ISO-classified environments sustainably.

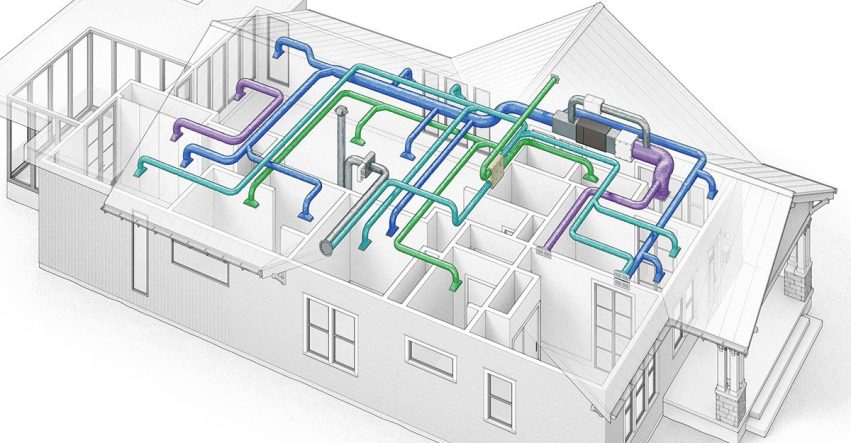

Pre-insulated / GI Ducting

Engineered ducting (PI/GI) with validated leakage class supports clean airflow distribution and pressure zoning.